Nivel:

Nivel:

Licenciatura

Título otorgado:

Ingeniería en Tecnologías de Manufactura.

Duración:

9 Semestres

Descripción carrera:

La carrera de Ingeniería en Tecnologías de Manufactura (ITMA), ha sido diseñada para cubrir diferentes funciones dentro del sector industrial, teniendo como sus tres pilares modulares, la automatización y control de procesos, el diseño avanzado y la administración de procesos. El conocimiento es transmitido a los estudiantes mediante el enfoque de competencias, permitiendo así, mejorar sus habilidades y destrezas tanto sociales como cognitivas para enfrentar los desafíos en diferentes ámbitos laborales. Al inicio de su carrera, se tienen las asignaturas básicas que sustentan estos tres pilares mencionados, donde se establecen las leyes físicas, el razonamiento matemático y lógico, así como, la socialización del estudiante con su entorno.

La administración, le permite al estudiante mejorar aspectos de calidad de procesos y productos, así como, la coordinación y dirección de personal, mientras que el diseño avanzado genera una visión más allá de la aplicación técnica del conocimiento que, combinada con la automatización y control de procesos incrementa el campo de acción del egresado

El uso de las tecnologías para el proceso enseñanza-aprendizaje, es una constante en el quehacer del estudiante, iniciando con software calificado para el desarrollo de prácticas (en los primeros semestres), hasta la utilización de tecnologías de automatización y control (a partir del cuarto semestre), así como, el manejo de máquinas-herramientas, sistemas de medición e inyectora de plásticos, dando como resultado un aprendizaje significativo que le permita una mejor inserción y adaptación al campo laboral. Una de las mayores fortalezas de la carrera es sin lugar a dudas el Centro de Manufactura Avanzada, el cual ha sido avalado y reconocido por la empresa FESTO ® como un Centro de Entrenamiento Certificador FESTO (FACT), donde se desarrollan las prácticas de los estudiantes y se realizan exámenes prácticos de certificación.

Al término de las asignaturas, los alumnos de ITMA deberán desarrollar un trabajo de residencia profesional, el cual consiste, en laborar durante 480 h Como mínimo en una empresa con la encomienda de realizar un proyecto avalado tanto por la empresa como por la universidad y que es considerado como parte de su evaluación de proyecto profesional.

Los estudiantes de ITMA, cuentan además con un club de robótica donde pueden participar en competencias tanto nacionales como internacionales, esto les permite también, mejorar sus habilidades y destrezas desarrollando aún más el razonamiento lógico y la programación.

Se cuenta también, con un programa de inserción laboral preliminar de los estudiantes en el sector industrial llamado COOP el cual está diseñado para aquellos alumnos que se encuentren del sexto semestre en adelante, con mejor promedio y buen dominio del idioma inglés. Consiste en permitir a la mitad de un grupo de alumnos (normalmente reducido) y que cumpla con los requisitos mencionados, para que asistan durante un periodo de tres meses a la industria, mientras la otra mitad estudia generando un proceso de aprendizaje Universidad-empresa.

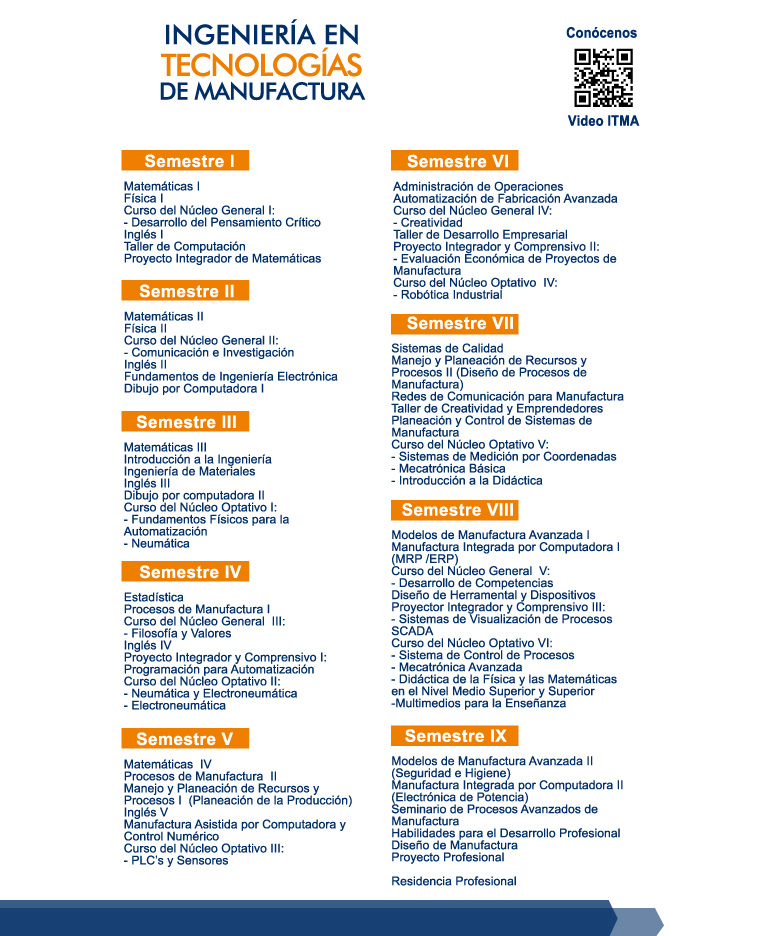

Plan de estudios:

Infraestructura / Recursos:

Ver CMA

Certificaciones:

Las certificaciones que ofrece la carrera son:

|

Se cuenta también con la certificación Lab View (CLAD)

Como puede verse, las certificaciones están inherentemente relacionadas con la mayoría del equipamiento con el que cuentan los laboratorios de ITMA. También se tienen los siguientes cursos de los cuales aunque no se certifican, si juegan un papel importante en el desarrollo de las competencias para un Ingeniero en Tecnologías de Manufactura

|

Mientras que las asignaturas que requieren del uso de software y computadora son:

|

Logros / Distinciones:

- 2° lugar en concurso robótica organizado por la IEEE en Brasil de 2008

- Primer lugar de Labview Robotics Challenge 2012.

- Primer lugar del 4° Torneo Internacional de Robótica “Vex Robotics”, Saltillo 2013 (Categoría Diseño).

- Primer Lugar del 3er Torneo Regional de Robótica Vex-Reeduca, San Luis Potosí 2013 (Categoría Excelencia y Campeón del Torneo).

- Primer Lugar del 2° Torneo Regional de la Academia de Robótica Vex-Reeduca, Aguascalientes 2014 (Categoría Diseño).

- 7° lugar del ranking mundial del Campeonato Mundial Vex Robotics en Anaheim, Cal. 2014.

A continuación se presentan los diferentes concursos en donde se aprecia a los integrantes autoridades y estudiantes.

- El pasado mes de febrero de 2016 los estudiantes del 6° y 8° semestre de la carrera de Manufactura obtuvieron el primer lugar del primer concurso anual de robótica ABB, organizado por la misma empresa ABB y que se llevó a cabo en las instalaciones de campus de Manufactura e Ingeniería de ABB, obteniendo como premio un Robot ABB modelo IRB 140.

Participaron los estudiantes:

Eli Israel Méndez López 130415 semestre 6°

Roberto Vargas Martínez 130415 semestre 8°

Antonella Argüelles Gutierrez 120877 semestre 8°

Armando de Jesús Hernández Niño 120063 semestre 8°

Asesor: Maestro Juan Rocha Chavarría.

Docentes:

MTRO. MIGUEL ANGEL ESPARZA ARANDA

Correo: miguel.esparza@upslp.edu.mx

Estudios: Ingeniero Mecánico Electricista por la UASLP y Maestría en Administración de Empresas por la UAEM. (Universidad Autónoma del Estado de México y Maestría en Control por la UNAM (no titulado)

Fecha de Ingreso a la universidad: enero de 2002 con PA y agosto 2003 como PTC

Participó en la selección del equipamiento de los laboratorios de Manufactura, visitando a diversos proveedores en diferentes partes del país como del extranjero, principalmente U.S.A., Alemania, España y Francia.

Área de especialidad: Manufactura y Administración

Trabajos de colaboración con otras instituciones educativas o empresas: 40 años de trabajo en diferentes Empresas y 43 años impartiendo clases en diferentes instituciones educativas:

- Instituciones Educativas tales como la UASLP, el ITESM, tanto en Querétaro como en San Luis Potosí y en la Universidad Autónoma del Estado de México (UAEM) en esta última también como encargado del área de Manufactura.

- Empresas tales como: Chrysler de México S.A. de C.V, Fabricas Autocar Mexicana S.A. de C.V, Imperial Eastman S.A. de C.V, Maquinas de Proceso S.A. de C.V, AC Mexicana, S.A. de C.V., Muebles Industrializados S.A. de C.V. y Plásticos y derivados GAMA, S.A. de C.V. DE 1966 a 2006 los últimos 5 años como propietario de Plásticos y Derivados GAMA

Aportaciones o logros: Experiencia adquirida durante 40 años de trabajo en la industria, de los cuales los últimos 20 año a nivel Dirección. Experiencia docente adquirida impartiendo de 3 a 8 horas a la semana desde el año de 1966 y a partir del 2003 como Profesor de Tiempo Completo y Coordinador de la carrera de Manufactura. Estando en diferentes empresas impartía 3 horas después de las 18 horas.

DR. MARGARITO MARTÍNEZ CRUZ Nombre: Margarito Martínez Cruz Correo: margarito.martinez@upslp.edu.mx o bien drnartinez@gmail.com Estudios: Doctorado en Ingeniería eléctrica, Maestría en Ingeniería, Licenciatura en Ingeniería Eléctrica todo en la Universidad Autónoma de San Luis Potosí. Niveles de investigación: básica, científica y tecnológica Apoyos como el SNI y el Prodep: Candidato de 2011-2014 y Perfil deseable 2015-2018 Fecha de Ingreso a la universidad: febrero del 2009 Área de especialidad: Automatización y control de procesos industriales, electricidad y electrónica industrial, Matemáticas aplicadas. Trabajos de colaboración con otras instituciones educativas o empresas: Con IPICyT: Harmonic Rejection Control Scheme for PWM DC/AC Power Converter y Average current controlled switching regulators with cascade boost converters. Con CANACINTRA: Participó como miembro del comité evaluador del el primer premio San Luis Potosí de Tecnología e Innovación San Luis Potosí. El doctor Margarito Martínez Cruz es ingeniero electricista, tiene el grado de maestro y doctor en Ingeniería eléctrica por parte de la Universidad Autónoma de San Luis Potosí en el área de control automático. Ha tenido la oportunidad de estudiar dos diplomados en educación, una por parte del Instituto tecnológico Superior de San Luis Potosí y otro por parte de la antes CUP. Ingresó a la Universidad Politécnica de San Luis Potosí en Febrero del 2009 como profesor de tiempo completo, actualmente es Profesor Investigador nivel B, ha sido candidato en el Sistema Nacional de Investigadores (SNI) durante el periodo Enero del 2012 a Diciembre del 2014, miembro de la asociación de México de control automático AMCA, de la SMCTM y de la SOMIM y actualmente es perfil deseable PROMEP. Cuenta con certificaciones extendidas por FESTO y National Instruments. Su especialidad es análisis y síntesis de controladores para sistemas dinámicos, teniendo como áreas de interés a los sistemas electrónicos de potencia, máquinas eléctricas, fuentes de energía alternativa y tecnologías de manufactura. Publicaciones: El Dr. Martínez cuenta con 3 artículos de Revista, 13 de congresos nacionales e internacionales y ha dirigido 2 tesis de maestría.

ING. JOSE ANGEL JARAMILLO SANTACRUZ

Correo: angel.jaramillo@upslp.edu.mx

Estudios: en Ingeniería Industrial en electrónica, y Maestría en Manufactura

Niveles de investigación:

Apoyos como el SIN y el Prodep:

Fecha de Ingreso a la universidad: 25 junio 2007

Área de especialidad: Manufactura + Automatización

Trabajos de colaboración con otras instituciones educativas o empresas: CIATEQ,

Datiotec, IMEU, Casa de moneda, Remy, PGI

Aportaciones o logros:

El Ingeniero José Ángel Jaramillo realizó sus estudios de Ingeniería Industrial en Electrónica, así como la maestría en Manufactura en el Instituto Tecnológico de San Luis Potosí , cuenta con una serie de más de 25 certificaciones en diversas tecnologías de automatización y manufactura, otorgadas por diversas empresas tales como, Cloos Gmbh, Karl Zeiss, Institute SLV, Festo, Mitutoyo, Kuka, Main Casa.

Tiene una experiencia adquirida durante 20 años de trabajo en la industria, de los cuales los últimos 15 años a nivel Gerencia. Experiencia docente de más de 25 años adquirida en diversas instituciones de nivel medio y superior como: ITSLP, Conalep, UVM, UASLP, UTSLP, UPSLP, CIATEQ,

A partir del 2000 como Profesor Investigador en la UTSLP y a partir de 2007 como profesor de Tiempo Completo en la UPSLP.

Su área de especialidad es la manufactura metal mecánica por medio de equipos con tecnologia CNC y sistemas flexibles de manufactura.

Impulsó la creación de motores de combustible sólido en el ITSLP ,se ha desempeñado como presidente del Cuerpo Académico de Ingeniería Industrial en la UTSLP de 2004 a junio de 2007, donde promovió la LGAPC enfocada a Desarrollo de estación de visión para medición de piezas metal mecánicas. Aplica exámenes de Certificación en tecnologías de automatización a través del centro FACT GOLD C0102010 a estudiantes interesados en obtenerla, Funge actualmente como responsable de laboratorios y talleres del Centro de Manufactura en la UPSLP.

Perfil de egreso:

El Ingeniero en Tecnologías de Manufactura será capaz de atender las necesidades emanadas de los procesos de transformación de productos manufacturados, contribuyendo al desarrollo local, regional y/o nacional, a través de las siguientes funciones:

• Desarrollar procesos de manufactura para incrementar la competitividad de la empresa mediante tecnologías adecuadas.

• Desarrollar manipuladores de producción para mejorar la productividad y calidad de la producción.

• Desarrollar la programación de los equipos de Control: PLC y sensores y Robots, así con CNC para cumplir los programas de la planta y satisfacer al cliente.

• Desarrollar programas de mantenimiento para cumplir los programas de la planta y satisfacer al cliente.

• Gestionar sistemas de calidad acordes a los estándares internacionales

• Gestionar sistemas de producción y calidad acordes a los sistemas de empresas de clase mundial.

• Formular proyectos de manufactura desde el punto de vista económico y tecnológico

• Utilizar las herramientas Lean manufacturing, para mejorar la productividad y la calidad.

VALORES, ACTITUDES Y HABILIDADES

a) VALORES.-Honestidad; Calidad en el trabajo y Espíritu de Servicio.

b) ACTITUDES.- Positiva y de cooperación.

c) HABILIDADES.- Capacidad para resolver problemas, Iniciativa y Toma de decisiones, , Espíritu emprendedor

Campo de trabajo:

El ingeniero en Tecnologías de Manufactura egresado de la UPSLP adquiere competencias necesarias como para desarrollarse profesionalmente en todas y cada una de las empresas manufactureras como por ejemplo químicas, metalmecánicas, alimenticias, automotrices, aeronáuticas, de fundición, industrialización del hule, plásticos, mineras, farmacéuticas, centros de investigación y desarrollo tecnológico, entre otras.

Ligas de interés:

Contacto

Mayra Daniela Martinez Contreras

Asistente de Coordinación de Manufactura.

Teléfono: 444 812-63-67 o 444 812-65-19 Ext. 253

E-mail: mayra.martinez@upslp.edu.mx

Mtro. Miguel Ángel Esparza Aranda

Coordinador de Ing. en Tecnologías de Manufactura

Teléfono: 444 812-63-67 o 444 812-65-19 Ext. 253

E-mail: miguel.esparza@upslp.edu.mx